Standard processes

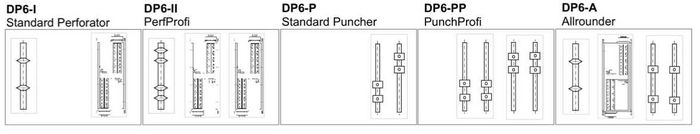

Dynamic perforation and punch module DP6

Dynamic perforation and punching combined in a modular concept. In 2-up production this permits individual processing of the two web halves. Combined use of three different functions is possible in a single module (dynamic perforation in the longitudinal and transverse direction, dynamic file hole punching). The Dynamic Perforation Module DP6 is integrated into the latest Hunkeler human line interface solution. Linking of orders with the perforation patterns supports the user with fast and secure production line setup in that the appropriate pattern is automatically retrieved for job selection.

The equally dynamic file hole and form punching unit integrated into the DP6 perforation module is so far unrivalled on the market. Possible application areas include trans- promotional applications with individual perforation or coupon production with security punching.

Punching and perforating module PP6

The PP6 was designed for in line finishing of unprinted paper rolls (sprocket hole punching, longitudinal and transverse perforation, fold perforation, file hole punching, form punching etc.) with the typical application areas of trans- actional and transpromotion printing in data centres.

Simple operation: The perforation cylinders can be changed by the operator and the other tools are maintained via cassettes. The active web cleaning and the evacuation of the confetti through the tools guarantee a clean and dust-free web. For the registration of the printer in pinless mode an optional print unit prints a top of form mark.

Standard processes

|

Web width

20.5'' 520mm | Unwinding | Punch/Perf | Punch/Perf |

|---|---|---|---|

|

|

|

|

|

UW6

|

PP6

|

DP6

|